Lifting Solutions for Jigs and Fixtures

Jig and fixture design is the process of creating devices that support, hold, or position parts during machining, assembly, or inspection. Fixtures are widely used in industrial manufacturing to ensure precision, consistency, and efficiency in the production process.

Common Types of Fixtures:

- Jig: A fixture that guides cutting tools or precisely positions parts during machining. For example, a drilling jig positions the drill bit at the required location on the part.

- Fixture: This device holds parts firmly during machining but does not guide cutting tools. For instance, a milling fixture secures the part during the milling process.

- Inspection Fixture: Used to check the dimensions, shape, or position of parts after machining or assembly, ensuring they meet technical specifications.

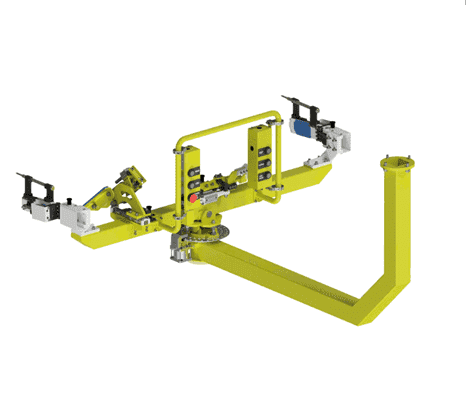

Actual Images of Fixtures Designed & Manufactured by Vietmani

Fixture Design Process:

- Requirement Analysis: Understand the product requirements, production processes, and technical specifications that need to be achieved.

- Material and Structure Selection: Choose suitable materials and fixture structures to ensure durability, accuracy, and cost-effectiveness.

- Detailed Design: Draw and simulate fixture designs using CAD software to ensure feasibility and effectiveness.

- Fabrication and Testing: Manufacture the fixture based on the design and conduct tests to check accuracy and performance.

- Refinement: Adjust the design based on test results to optimize the fixture before it is officially used.

Fixture design is a crucial part of the manufacturing process, helping to improve product quality, increase efficiency, and ensure safety during machining and assembly.

Contact Vietmani for solutions and quotations:

Hotline : 0931 782 489 --- Email: [email protected]